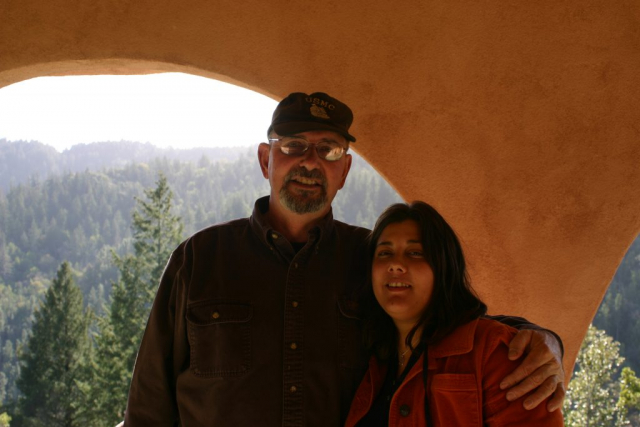

We purchased 70 acres of raw land in Cazadero in 2007 and logged 3 acres on King Ridge Road to build a house. This is a pictorial storyline of this house project. This is where Susan and I live along with 2 cats, Egypt & Bhuvon, and our dog - Phi. Our daughters are grown and on their own.

One of the first things I did before purchasing the land was talk to Ed Fisch from Fisch Bros. Drilling. Ed and I met at the property and he said "I am going to tell you something I hardly ever say". I said "what?" He said "You have water". He knew the area and he knew it had water. The drilling rig showed up on 8-27-07 and drilled 180 feet in less than 2 hours. The driller asked me if I wanted to go deeper? I asked how much water is the well producing? He said "50 gallons a minute". I said "that's enough". The requirement to build a house is 1 gallon a minute. The 2500 gallon tank is for fire suppression.

Using a Lucas Mill and skid steer I rented from my neighbor Bob Mann we cut the Fir logs into lumber for the house and milled the Oak and Madrone into lumber for future furniture projects. We left the Redwood trees standing.

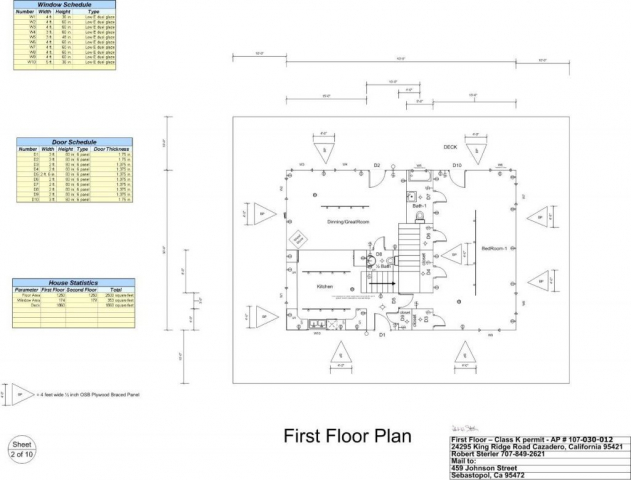

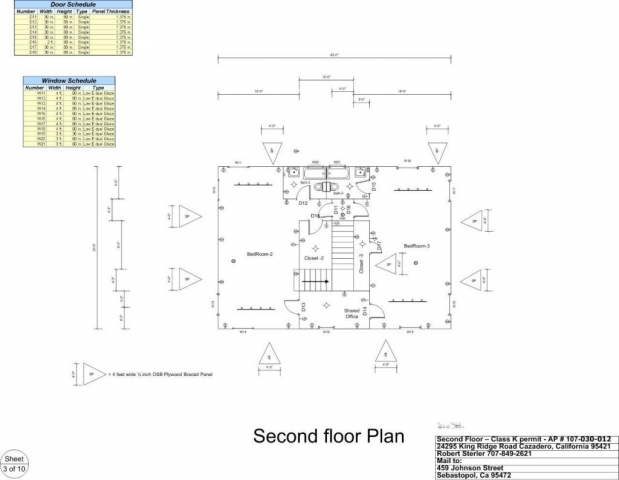

The design was drawn on my computer. I got a class K permit which allows for alternative building. Under class K my self produced lumber did not require a inspection stamp. Bob Mann expertly dug the foundation with an excavator. We formed the foundation and concrete went in and we started to frame around the beginning of 2008.

The framing of the house was done by myself and primarily one helper - Brian. Brian also helped me mill the logs into lumber. Brian did not have previous carpentry experience.

Things moved along slowly in the framing process because I was close to 60 years old and I was FAT. However, I keep at it and Brian and I got the job done.

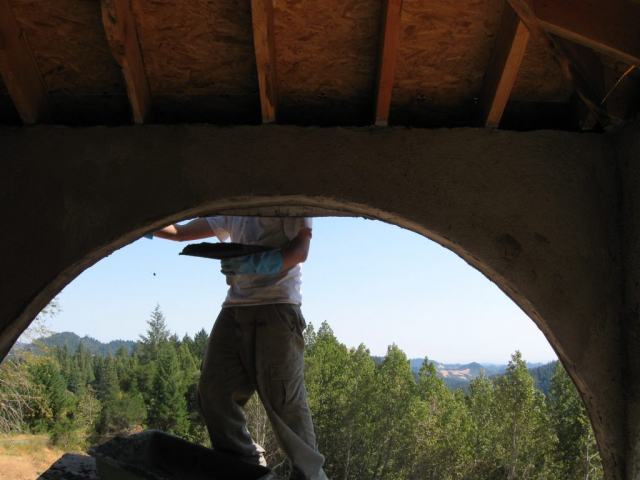

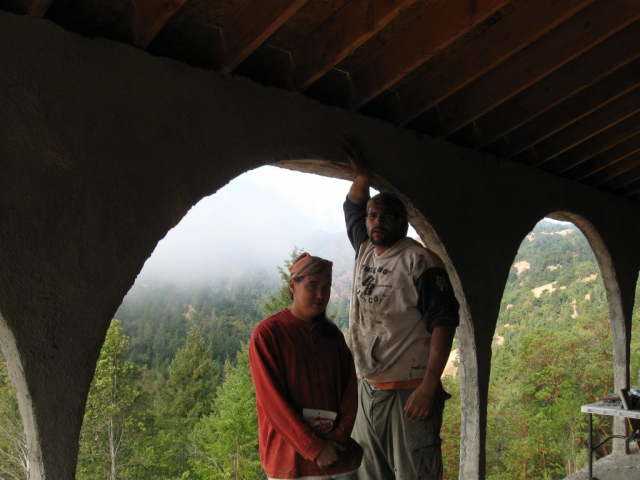

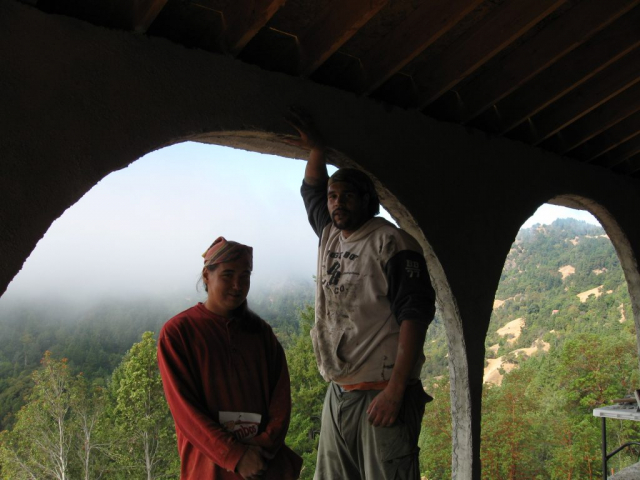

After framing I hired many more people to stucco the house. None of my workers had any experience in stucco. I demonstrated each step from paper wire, mixing, transporting and applying stucco. There is no getting around the fact that stucco is just brutally hard work.

Old school stucco is 3 coats - scratch - brown - top. 3 coat Stucco is one inch thick concrete and a lifetime siding. The brown coat is when the surface becomes smooth, flat and even. There are tricks to the trade to make this happen. Stucco is just very hard work at every stage - mixing - transporting - applying. Notice this is a 3 story house.

The top coat is also called the finish or color coat. I wanted to share some pictures of mixing stucco which is done with a shovel, sand, 100 pound bags of stucco, 5 gallon bucket, water and cement mixer. Wet stucco is wheelbarrowed and/or carried or hoisted in 5 gallon bucket to wherever it is needed. All hard work that will test your endurance. One gentleman I hired was 7 feet tall - he did all the arches without a step stool. The last coat (color) is done from the top down.

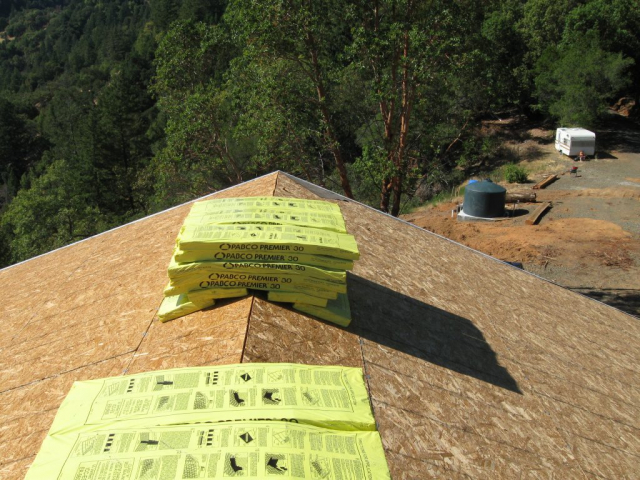

After stucco we put on the roofing and the house was water tight. We painted the trim green to look like boards; however all the exterior is stucco because stucco does not rot or burn! The roof also will not burn. Here is some pictures of my neighbor Bob Mann installing the septic system.

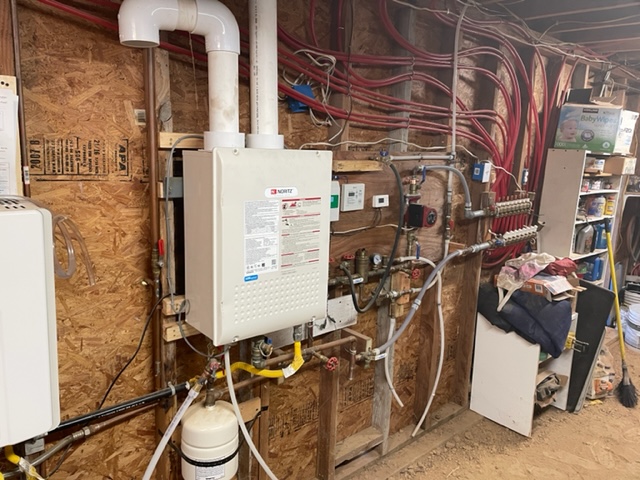

It took me about 1 year from foundation to get the house water tight. Then the wet season arrived and I installed Electrical, plumbing, heating inside the house with a great (free) helper - my sister Lynne. Other family members helped sometimes, but Lynne was there everyday. Lynne was living with us in Sebastopol at this time and we drove in my truck to work everyday! The drywall was hung and taped by professionals. The taping was smooth wall finish. Lynne & I spray painted all interior walls white. Next, Lynne & I installed radiant floor heating.

Lynne & I installed all of the 5/8 inch vertical grain bamboo flooring.

We have 70 acres which is more than 3 million square feet of land. My neighbor, Bob Mann, excavated our own rock quarry for road base for a circular driveway. He also paved 20 feet wide driveway all around the house. He transported the rock up to the house area and spread it out with a bull dozer. Then he used a steam roller to compact it. It is a lifetime roadway. Otherwise in the rainy season the road would be a mud pit. Also some pictures of the finished deck and railings which I welded together from 3/4 inch black pipe and 1/2 inch rebar.

Next I built a curved entry way in the front of the house. The structural beams are not commercially available. So I made a form and manufactured my own glue laminated structural support beams. All of this staircase was Cazadero Douglas Fir that I had milled.

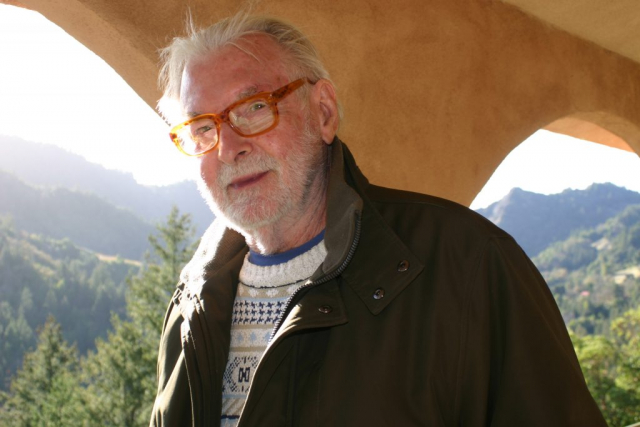

On 11-10-09 I turned 60 years old. So we had a birthday party in Cazadero. My neighbor, Bob Mann, played and sang for 4 hours. He has a beautiful baritone and people came from far and wide.

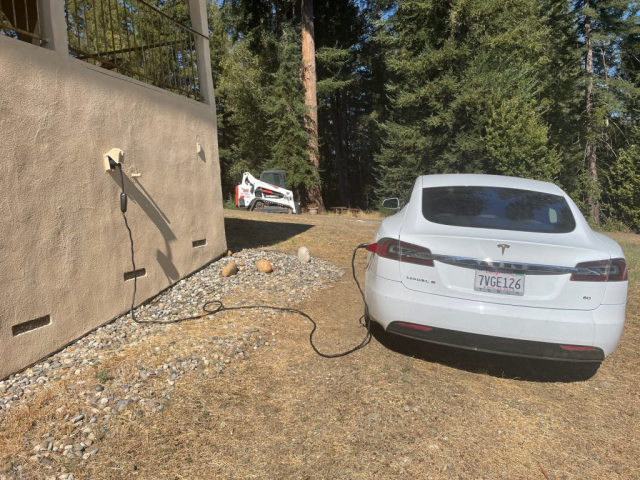

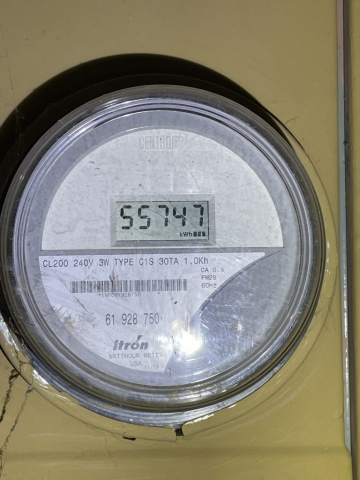

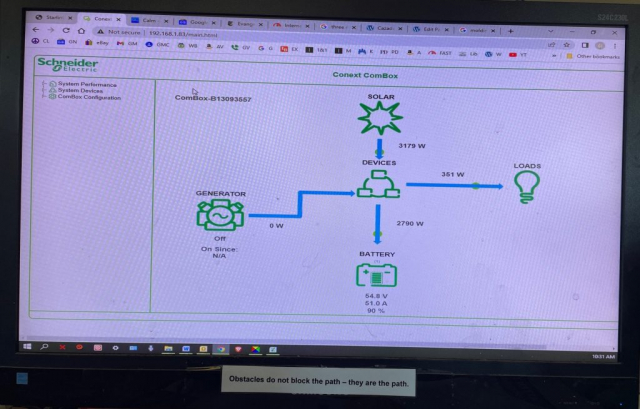

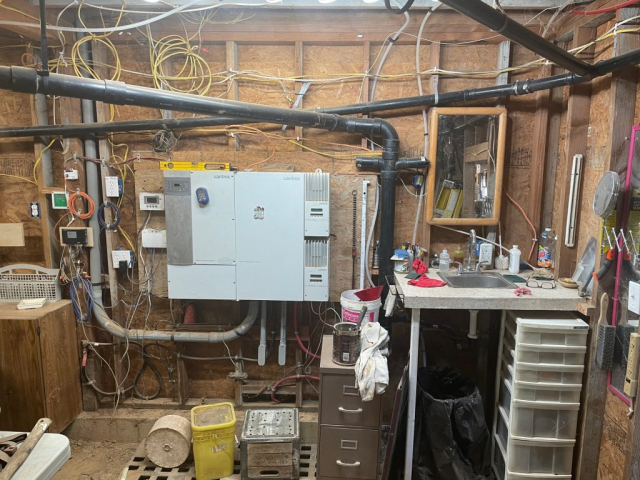

The solar system was installed by myself and a neighbor, Larry. We are completely off grid - not connected to PG&E. After my batteries are full, usually before 12 noon - all unused electricity is dumped into the ground. I still contemplate the making of hydrogen by electrolysis and storing it, but I have not done it yet. We are never out of power and feel spoiled electrically with our over abundance. Our system has been up for about 13+ years and we use about 8 to 12 KWH per day. Over the last 6 years we run more electricity through the house because we charge the Tesla with our solar power. If I am charging the Tesla, I do not use my 20" planner (5HP motor @ 240 volts) because our electrical system is 6 KW max. Unless I manually turn the generator on in which case we can use up to 14 KW. Over the lifetime of the system we have used 55747 KWH in and thru the house. We have a propane backup generator and the solar computer will turn it on and off automatically if the batteries get low because of no sun. I can monitor and control the entire solar system from my desktop or phone.

All of the tile work was designed and installed by me: floors, countertop, woodstove, showers and bathtub. The bathtub will hold 150 gallons and two large people can face and wash each others feet - comfortably. The kitchen cabinets are from IKEA. Susan said we needed to buy cabinets because I am too slow at furniture making. She, as usual, is correct. There is an outdoor shower and tub spout on the back deck which is handy for both people & animals.

All of the windows are made by Anderson (vertical grain Douglas Fir with exterior vinyl cladding) All doors are solid core exterior vertical grain Douglas Fir. Interesting exterior doors (1.75 inches thick) are cheaper than interior doors (1.375 inches thick). All doors are exterior grade. All trim for windows, doors, jams and floor molding was manufactured by me from Cazadero vertical grain Douglas Fir that I cut on the sawmill and segregated just for trim. All interior wood finishes are Tung Oil.

The house basic footprint is about 1400 square feet. 3 bedrooms and 4.5 bathrooms in 2800 square feet living space. The first floor is 10 foot ceilings. The second floor is a cathedral ceiling that reaches 13.5 feet. The deck surrounds the house and is 10 feet wide and 2000 square feet total - covered and waterproof. So, the basement is 3400 useable square feet. The basement is where my shop is located. I installed a 5th toilet and 2 separate sinks in the basement.

Here are some aerial photo's of the property.